Roll Forming Machine

GENERAL INFORMATION

Roll forming machine is a machine that continuously bends a steel coil or a strip by numbers of forming rollers which is sequentially arranged to form a specific section profile. Roll forming has been evolved into the most effective steel strip forming technology. As an important structural component, cold-formed steel products have been widely used in many fields such as construction, automobile manufacturing, shipbuilding, electronics industry and machinery manufacturing. It is the user's variety, specifications and quality of cold-formed steel products, that have prompted the rapid development of cold forming technology.

APPLICATION

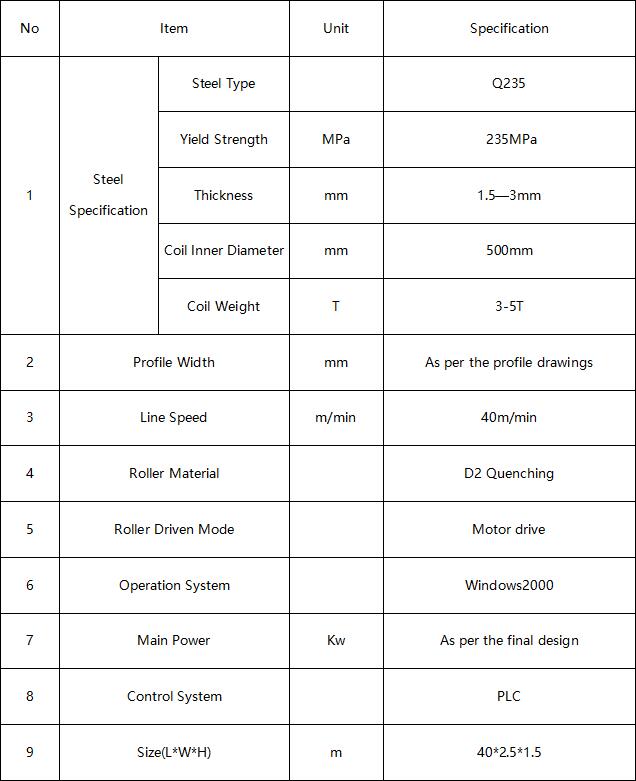

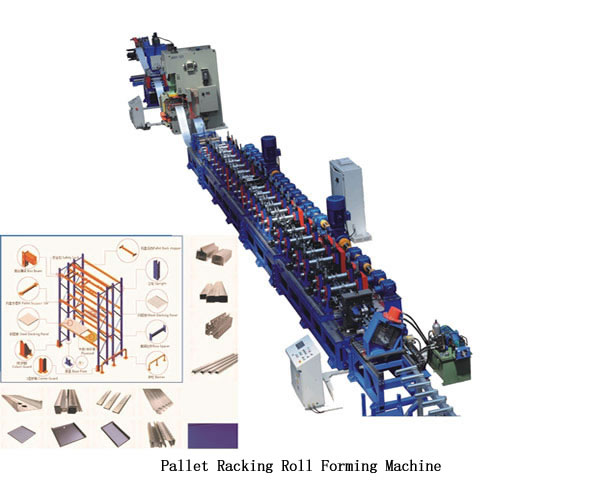

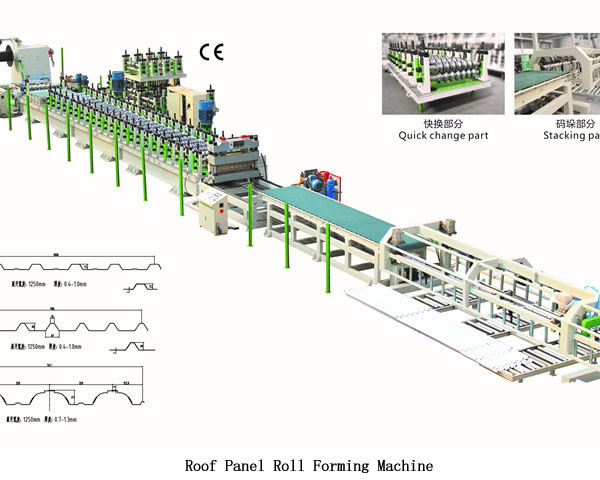

Roll forming machines are mainly used in steel structure industry (to form C&Z purlin, floor decking, roof and wall panels, etc.), environmental protection industry (anode plate, and protection panel, etc.), traffic industry (highway guardrail), automobile industry (board, bumper, automobile girders), logistics and warehouse storage industry (Upright, beam, bracing, and shelf panel), cable tray industry, coal mine special W support, three-dimensional garage industry (wave and side beam), and PV solar rack, etc.

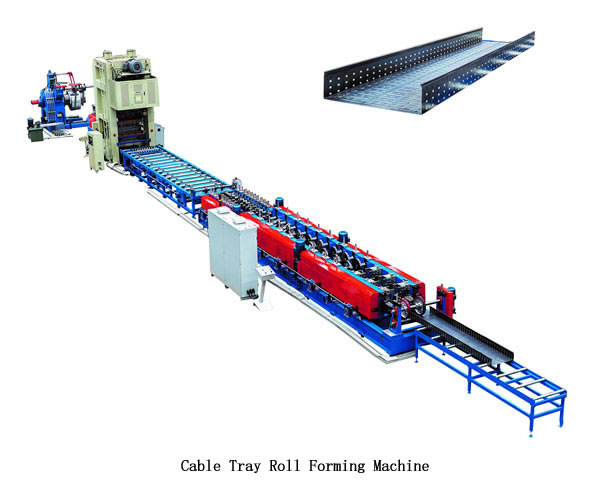

TECHNICAL SPECIFICATION

(Take upright roll forming line as an example)

Pallet racking (Upright) roll forming line includes de-coiler, leveler, feeding device, punching, roll forming, cutting, and run-out. It adopts Siemens PLC, touch screen input, high degree of automation, convenient operation, high production efficiency, and the whole line production speed can reach 40m/min.